Flying observatory delivers information through MICROSENS converters

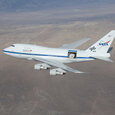

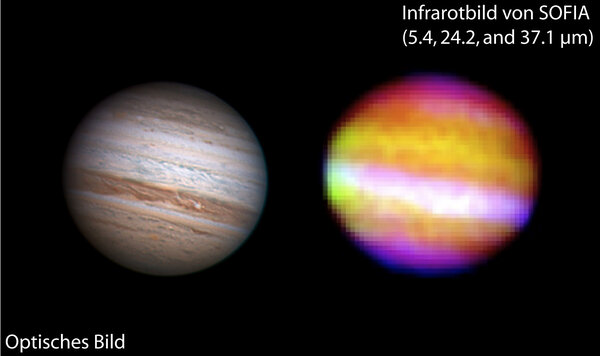

Gaining new insights into the formation of stars and into the centre of our home galaxy, the milky way - those are two of the ambitious objectives tackled by the SOFIA project. Infrared radiation provides important information on this. Although invisible to the naked eye, it allows us to draw conclusions about the composition of stars, the temperatures prevailing on them, and how new stars develop. Infrared radiation cannot be measured from the ground, however. The main obstacle here is the water vapour in the earth's atmosphere. To bypass this problem, measurements must be obtained either from outside the earth's atmosphere or at least from within the stratosphere. Measurements from outside the earth's atmosphere are obtained through so-called outer space telescopes. An exploration from the stratosphere affords a more flexible application, however. The infrared telescope was designed and built strictly with this idea in mind.

The German scientists were faced with numerous challenges, not all of them of an astronomical nature. They also had to take a lot of parameters into account when choosing the right transmission technology. It is true that the transmission medium to be used on board was selected very quickly. Fiber optics offered clear advantages: For one thing, the development team wanted the solution to be as light-weight as possible, while at the same time avoiding electromagnetic interference at all cost to prevent any falsification of the results delivered by the sensitive measuring equipment on board. Even the use of standard components, however, turns out to be an adventure in such an environment. The required media converters therefore had to work 100% reliably in order to not affect the measurements.

The task of a media converter is actually not all that spectacular: All it does is connecting copper cables with fiber optic links. The data to be transmitted is converted physically from one medium to the other. If this conversion takes place in an airplane at a height of about 13 kilometres, however, and if the data to be transmitted consists of infrared radiation measurements from outer space, that are to provide insights into the formation of young stars, the project all of a sudden takes on a completely new dimension. "We need to ensure a smooth data transfer on board. That is why we take the greatest care to use high-quality components," says Dr. Holger Jakob, director of the telescope assembly team at the German SOFIA Institute (DSI). "We put particular emphasis on fault tolerance and reliability." At this point, the scientists contacted MICROSENS. First of all, the company is regarded as one of the pioneers of fiber optic transmission technology. And secondly, it develops all its products in its own laboratory and then produces and tests them in its own factories in compliance with the highest quality standards.

Before a final decision could be made, however, numerous obstacles had to be overcome. Due to aerospace regulations stipulated by law, all on-board systems had to pass a number of elaborate vibration, pressure and temperature tests. After all, both temperature and pressure are subject to enormous variations during flights at a height of 13 kilometres. The strain this puts on all components involved exceeds any regular requirements by far. But even under these conditions, the systems performed flawlessly. Mathias Moessner, project coordinator at the DSI, explains it as follows: "The collaboration with the MICROSENS developers in Germany went very smoothly. Our requests were answered - and our requirements implemented - in a fast and extremely precise manner."

A network consisting of about a dozen media converters transmits all the data between the on-board measuring systems, the positioning control systems, the camera guidance system and the telescope drive system. To achieve this, some of the devices even had to be mounted on the movable parts of the telescope. The decisive advantage offered by these systems lays in their compact design, that enormously facilitated their installation into the highly compact electronic boxes. The flying observatory has by now successfully completed many flying hours, and scientists have managed to obtain some spectacular measurements. The media converters have been fulfilling their job smoothly since their first application in November 2010. Fascinating infrared images of the planet Jupiter, the Messier 82 galaxy, and the M17SW star formation region have been transmitted successfully. SOFIA has even been to Germany. In September 2011, visitors were able to view SOFIA on the Stuttgart Airport. Astronomers have scheduled several flights per week for the next twenty years. It is safe to assume that as yet unimaginable data volumes will be transmitted reliably, and exciting insights will be won.

SOFIA, the Stratospheric Observatory for Infrared Astronomy, is a joint project between the German Aerospace Centre (DLR; under contract 50 OK 0901) and the American National Aeronautics and Space Administration (NASA). Commissioned by the DLR, it is funded by the German Federal Ministry of Economics and Technology, based on a resolution by the German Federal Parliament, and by the state of Baden-Württemberg and the University of Stuttgart. The scientific operation is coordinated on the German side by the German SOFIA Institute (DSI) of the University of Stuttgart, and by the Universities Space Research Association (USRA) on the U.S. side.

About MICROSENS

Transmitting information via fiber optic connections offers numerous benefits. MICROSENS GmbH & Co. KG recognised this very early on. As one of the pioneers, the company has developed and produced high-performance communications and transmission systems in Germany since 1993. Individually matched to the demands of diverse usage areas and embedded in comprehensive concepts for individual sectors. But, above all, close to the customer. Technical challenges from customer projects are incorporated directly into product development. This way, IP-based automation solutions are created for modern buildings, cost-efficient network concepts for the office and workspace, robust and fail-safe solutions for industrial environments, optical transport systems future-oriented wide area networks and efficient coupling of sites and computer centres.